INNOVATIVE BINDING SOLUTION TO SOLVETHE FINES HANDLING PROBLEM

Is it possible to reduce environmental liabilities and process coal fines into a valuable product? Yes, this was the conviction of a team of experienced mechanical and chemical engineers when they started a research project in 2013. From the beginning, it was clear to the CoalTech team that any solution to this environmental challenge would only find wide-scale adoption if it was also financially attractive for coal miners and consumers.

Over the last six years, our specialists from South Africa and Italy have been working on a solution that solves this challenging problem. The research and development activities proceeded from lab scale demonstrations to small demonstration facilities and, at the end of 2018, to the commissioning of a first industrial-scale plant near Witbank (South Africa). This pilot project has shown excellent results since then.

The technology is now ready for scaling and roll-out globally. CoalTech S.á.r.l. (Luxembourg) and Creon Energy are responsible for the implementation of projects, where some adaption reflecting the prevailing climatic conditions, the specific composition of the coal fines, and regional regulations need to be taken into consideration in the construction of agglomeration plants.

These adaptations do not, however, require fundamental changes to CoalTech’s Next Generation Plant design, the core of which is agglomeration and drying process based on CoalTech’s proprietary binder. Through its local operator Creon Energy, CoalTech S.à.r.l. possesses the required engineering licenses to develop plants. We are therefore ready to engage with the industry and commence the roll-out of this technology.

INDEPENDENTLY VERIFIED

CoalTech adheres to strict test protocols — be it with respect to sampling during commercial operations, or when producing samples for potential clients. All results presented, such as strength/hardness, tumble and moisture resistance tests, have been verified independently by Bureau Veritas. Similarly protocols will be followed, pursuant to local regulations and in alignment with international norms.

KEY ADVANTAGES

CONSISTENT QUALITY

The binder does not alter the chemical (volatiles, ash, sulphur) or burning characteristics of the coal fines. We do not use undesirable chemicals, which may damage furnaces and flues.

ZERO INVESTMENT POLICY

While the implementation of CoalTech innovations leads to immediate results through utilization of coal waste, no investments are required by the coal mining or energy generating company.

FLEXIBLE CALIBRATION

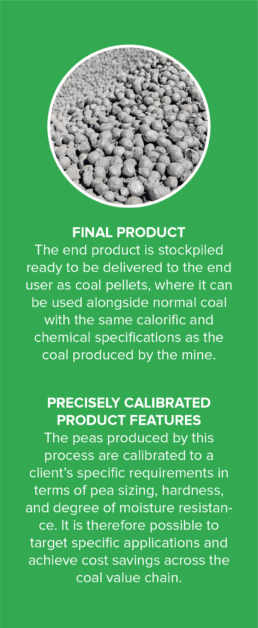

The product’s physical features such as hardness, moisture resistance, and size can be calibrated during the production process. It can thus be stockpiled and bulk-handled, ensuring easy integration with existing supply chains.

PROPRIETARY TECHNOLOGY

CoalTech has invested over USD 6 million to develop binder-based processing technology, which was proven as technically and economically viable at an industrial scale demonstration plant in South Africa.

KEY ADVANTAGES

CONSISTENT QUALITY

The binder does not alter the chemical (volatiles, ash, sulphur) or burning characteristics of the coal fines. We do not use undesirable chemicals, which may damage furnaces and flues.

ZERO INVESTMENT POLICY

While the implementation of CoalTech innovations leads to immediate results through utilization of coal waste, no investments are required by the coal mining or energy generating company.

FLEXIBLE CALIBRATION

The product’s physical features such as hardness, moisture resistance, and size can be calibrated during the production process. It can thus be stockpiled and bulk-handled, ensuring easy integration with existing supply chains.

PROPRIETARY TECHNOLOGY

CoalTech has invested over USD 6 million to develop binder-based processing technology, which was proven as technically and economically viable at an industrial scale demonstration plant in South Africa.

COAL PELLET CHARACTERISTICS

CoalTech provide a proven solution, suitable for all mining companies, coal power plants, chemical plants, and large users of coal worldwide. Our solution solves the handling and storage problem of fines, so the agglomerated product can be used as normal coal in all steps of the coal value chain. We do not alter the chemical characteristics of the coal and our product has the following features.

CALORIFIC VALUE

CV of Pellets

=

CV of Coal Fines

GREEN STRENGTH

80 drops in 2.5 mt. high tumbler

>=

+1+0mm / 15%

CALORIFIC VALUE

CV of Pellets

=

CV of Coal Fines

GREEN STRENGTH

80 drops in 2.5 mt. high tumbler

>=

+1+0mm / 15%

WATER RESISTANCE

120 min submerged

>=

20-25%

ASH CONTENT

% Ash of Pellets

=

% Ash of coal fines

WATER RESISTANCE

120 min submerged

>=

20-25%

ASH CONTENT

% Ash of Pellets

=

% Ash of coal fines

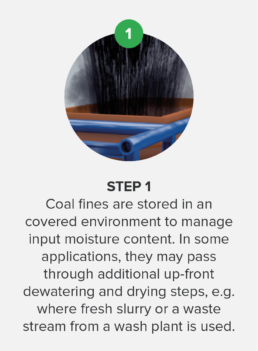

PRODUCTION PROCESS

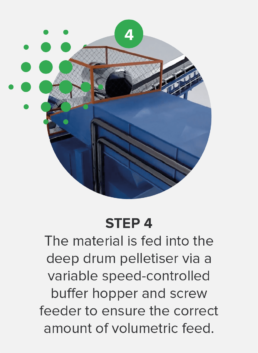

A proprietary binder and our carefully calibrated production process are the reason why our agglomerated coal fines maintain the characteristics of coal taken directly from mines. We do not disclose the ingredients, but below we set out the main steps of the process.